How 3D printing works

3D printing is a modern way of creating objects using various technological processes. It is an additive production, where electronic data is used to create a physical model in the form of gradually layered material - gypsum composite, various types of plastics, metals, waxes, resins or glass and ceramics. The source for the computer model can be CAD systems, 3D scanning using 3D scanners, scientific and technical data or data from medical imaging systems. The model created in the computer program is divided into thin horizontal layers and then sent to a 3D printer. The layers gradually harden until they combine to form the final product. The whole process takes only a few hours with the development of new technologies is getting shorter and time savings are one of the reasons why 3D printing is predicted for the future.

3D printing produces the resulting product by successively applying building material over very thin layers, which are joined together, for example by melting or gluing. Unlike conventional manufacturing methods, such as chip machining, where the material is removed, 3D printing can create challenging shapes and constructions than could be done in any other way than 3D printing. 3D printing is especially suitable for single-part and small-series production for fast production preparation. It is therefore often used for the production of functional prototypes, design models and tools in industry.

Who uses 3D printing

It can be said that all branches of human leadership are using 3D printing slowly. Full color 3D printing of gypsum composite is used by the advertising industry to present their designs. Architects and designers present their designs. Artists fully develop their imagination. Doctors are preparing for interventions and medical students are studying parts of the human body. The sales department of the companies are designing new products and restorers reconstruct irreversibly lost valuable artifacts. 3D printing simplifies a number of rather costly and complicated processes and processes and contributes to their further development.

3D print quality

The quality of 3D printing depends on the quality of the computer 3D model, but the quality of the 3D printer itself is crucial. Nowadays, the development of these devices is divided into two directions, where besides stands for professional and production use there are incomparably cheaper devices aimed at ordinary consumers from among technical enthusiasts and do-it-yourselfers.

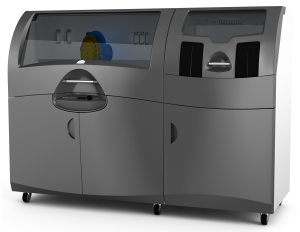

Our professional 3D printer

PROJET 660 Pro

ColorJetPrinting technology enables the only printing of full-color models of high-performance gypsum composite with a resolution of 600x540 DPI. The printing area of size 254 x 381 x 204 mm is water for printing of architectural and design models, fast production of non-functional prototypes, medical devices, but also for printing of human dummies. A layer thickness of 0.1 mm ensures high quality capture of details and small size models. The advantage is printing speed up to 28mm / h and the possibility to print several different models at the same time.